NORMACLAMP® - Hose Clamps

NORMACLAMP® GBS

or steel reinforcements and high shore hardnesses.

Heavy duty clamps to DIN 3017

Their distinguishing feature is the extremely high band tensile force.

NORMACLAMP® GBS are particularly suited for

The assembly of NORMACLAMP® GBS

is easily completed by

sealing suction and pressure lines with plastic

means of either manual, pneumatic or electric standard tools.

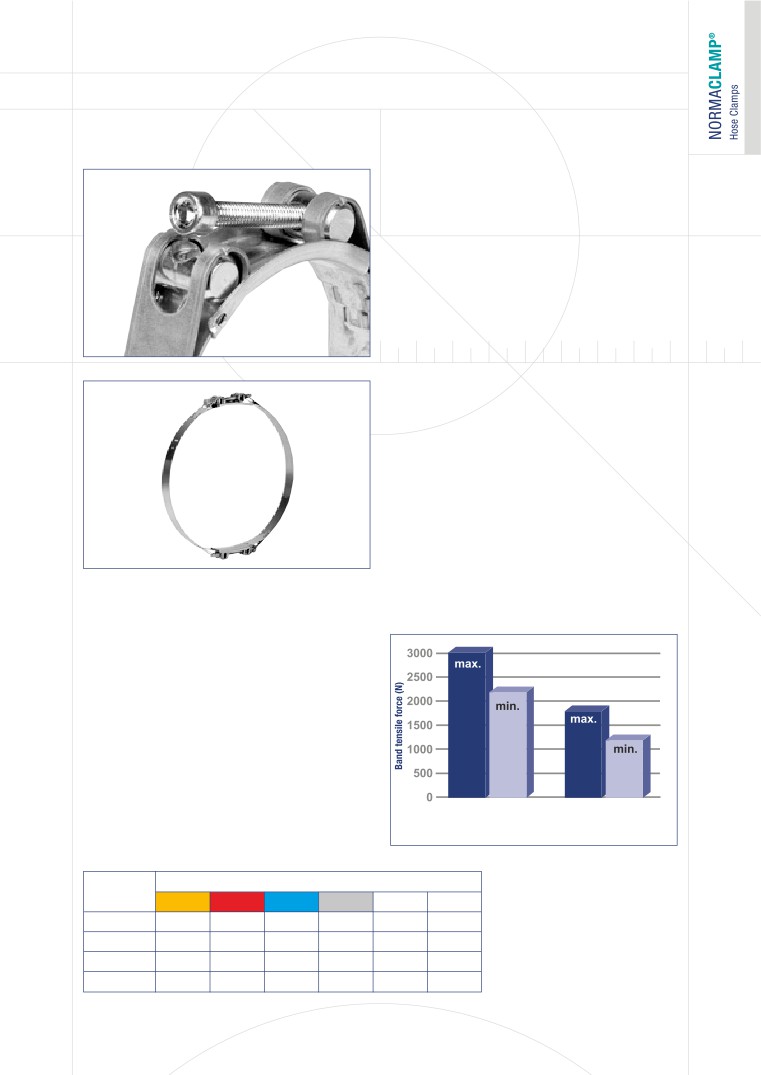

Short description of technical features

1

4

2

3

5

1

W1/W2/W4

3

Mechanically locked closure

New specially designed bolt with integrated spacer

= no welding points, no contact corrosion

= improved efficiency, cannot get lost

W5

4

Bridge = optimal hose protection

Hexagonal socket screw

5

Robust band with rounded edges

2

Reinforced loops

= protection against injuries and damage to the hose

= allow to withstand significantly higher torques

surface

Materials

W1*

W2*

W4

W5

x

x

x

x

* No Chromium VI used for surface treatment of closure unit

34

NORMACLAMP® - Hose Clamps

Clamp Types

NORMACLAMP® GBS

with QR closure

On request the NORMACLAMP® GBS is available with QRC

(Quick Release Closure). The hinged bolt can be quickly released

and enables the fast and easy assembly or disassembly of the

clamp.

Only available in W1 and W2!

NORMACLAMP® GBS

Multi-Part version

The 2-part version of the NORMACLAMP® GBS is an additional

clamp type in this range.

Technical features

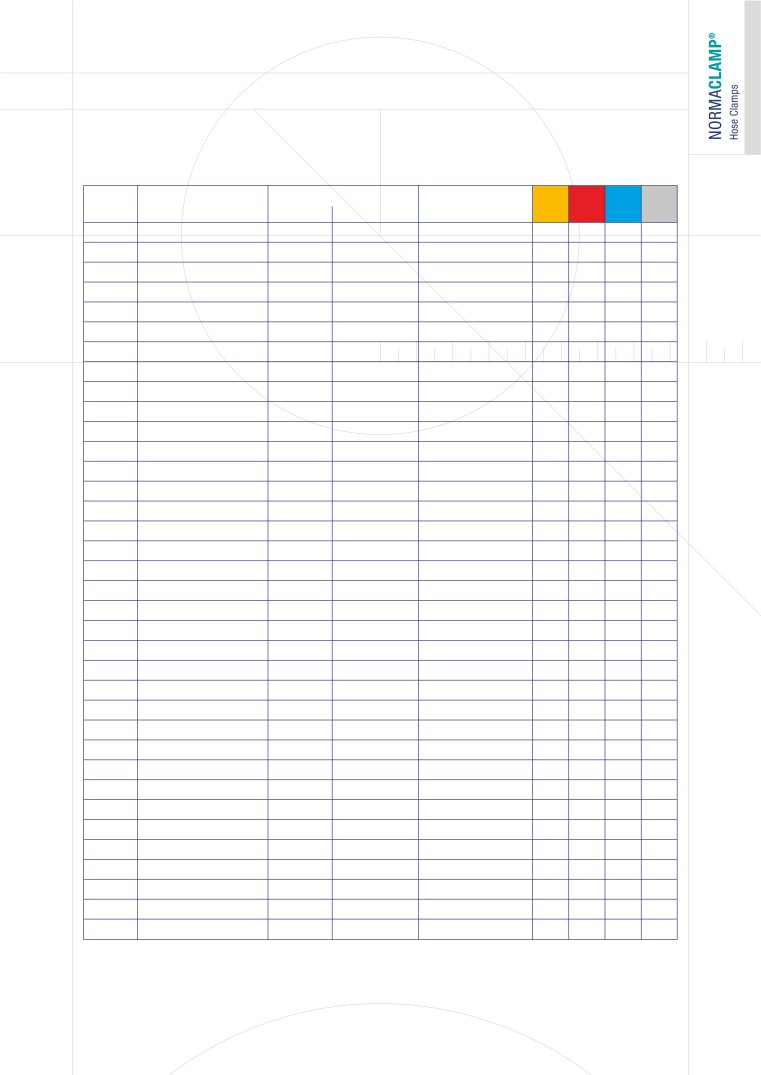

Band tensile forces

The results of numerous test sequences proved that NORMA-

CLAMP® GBS are superior to comparable competitive products:

NORMACLAMP® GBS 46/20

Competitive

W1 zinc-aluminium

product

Band width

Material thickness (mm)

(mm)

W1

W2

W4

W5

M

SW

18

0.8

0.6

0.6

0.6

6

8

20

1.0

0.8

0.8

0.8

7

10

25

1.0

1.0

1.0

1.0

8

13

30

1.3

1.0

1.0

1.0

10

17

35

NORMACLAMP® - Hose Clamps

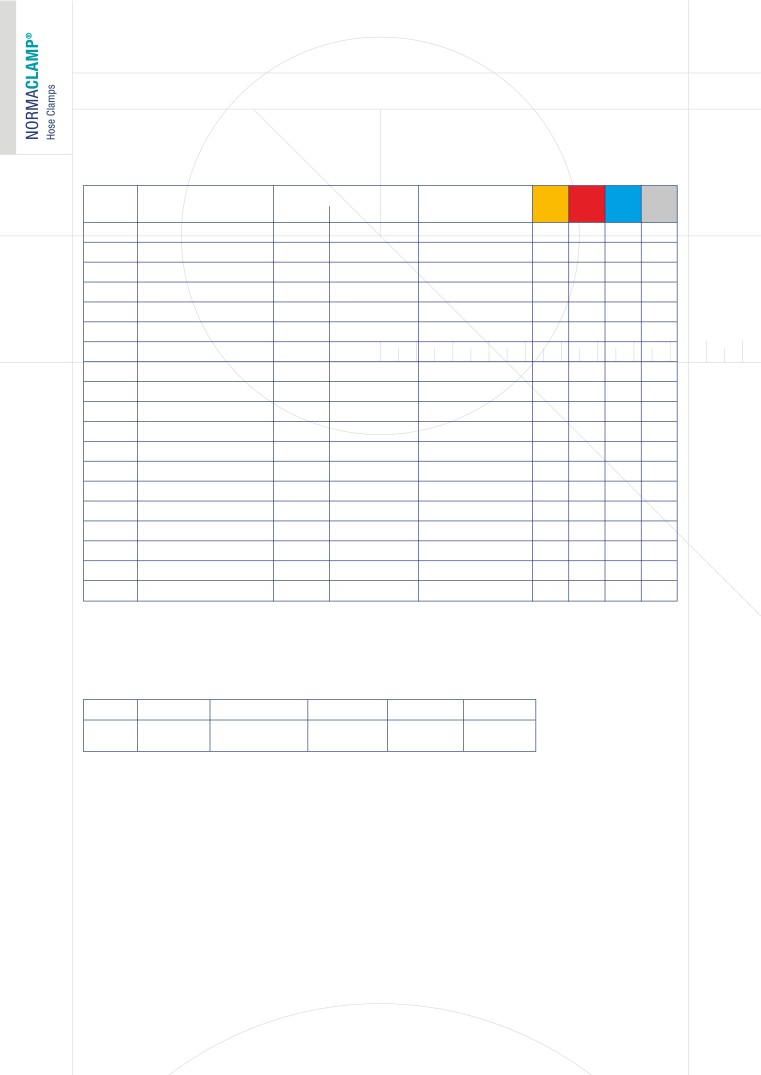

Torques

NORMACLAMP®GBS

Band width

Fracture torques (min.)

Recommended tightening torque

(mm)

W1

W2

W4

W5

18

15 Nm

15 Nm

15 Nm

15 Nm

8 Nm

20

25 Nm

20 Nm

20 Nm

20 Nm

10 Nm

25

35 Nm

30 Nm

30 Nm

30 Nm

20 Nm

30

50 Nm

45 Nm

45 Nm

45 Nm

25 Nm

NORMACLAMP®GBS QRC

Band width

Fracture torques (min.)

Recommended tightening torque

(mm)

W1

W2

18

10 Nm

10 Nm

6 Nm

20

15 Nm

15 Nm

8 Nm

25

25 Nm

25 Nm

18 Nm

30

40 Nm

40 Nm

22 Nm

Corrosion resistance

Material

Corrosion resistance in salt spray testing

W1

Min.

72 h

W2

Min.

72 h

W4

Min. 240 h

W5

Min.

400 h

Applications

The NORMACLAMP® GBS are specially suitable for use on com-

mercial and special vehicles:

• Sealing and retaining suction and pressure hoses with steel

or plastic reinforcements and high shore hardness.

The advantages at a glance

• Twofold improved failure torque

• Threefold improved band tensile forces

36

NORMACLAMP® - Hose Clamps

Survey of sizes, band widths & materials

NORMACLAMP® GBS

Band width

Clamping Range

Packaging

(mm)

Description

in mm

in Inches

PU

W1

W2

W4

W5

18

GBS M

17-19/18 SK*

17-19

1 1/16-3/4

50

X

X

X

X

18

GBS M

19-21/18 SK*

19-21

3/4-13/16

50

X

X

X

X

18

GBS M

21-23/18 SK*

21-23

13/16-7/8

50

X

X

X

X

18

GBS M 23-25/18 SK*

23-25

7/8-1

50

X

X

X

X

18

GBS M 25-27/18 SK

25-27

1-1 1/16

50

X

X

X

X

18

GBS M 27-29/18 SK

27-29

1 1/16-1 1/8

50

X

X

X

X

18

GBS M 29-31/18 SK

29-31

1 1/8-1 1/4

50

X

X

X

X

18

GBS M 31-34/18 SK

31-34

1 1/4-1 5/16

50

X

X

X

X

18

GBS M 34-37/18 SK

34-37

1 5/16-1 7/16

50

X

X

X

X

18

GBS M 37-40/18 SK

37-40

1 7/16-1 9/16

50

X

X

X

X

18

GBS M 40-43/18 SK

40-43

1 9/16-1 11/16

50

X

X

X

X

20

GBS M 43-47/20 SK

43-47

1 11/16-1 7/8

50

X

X

X

X

20

GBS M 47-51/20 SK

47-51

1 7/8-2

50

X

X

X

X

20

GBS M 51-55/20 SK

51-55

2-2 3/16

50

X

X

X

X

20

GBS M 55-59/20 SK

55-59

23/16-25/16

50

X

X

X

X

20

GBS M 59-63/20 SK

59-63

2 5/16-2 1/2

50

X

X

X

X

20

GBS M 63-68/20 SK

63-68

2 1/2-2 11/16

50

X

X

X

X

25

GBS M 68-73/25 SK

68-73

2 11/16-2 7/8

25

X

X

X

X

25

GBS M 73-79/25 SK

73-79

2 7/8-3 1/8

25

X

X

X

X

25

GBS M 79-85/25 SK

79-85

3 1/8-3 3/8

25

X

X

X

X

25

GBS M 85-91/25 SK

85-91

3 3/8-3 9/16

25

X

X

X

X

25

GBS M 91-97/25 SK

91-97

3 9/16-3 13/16

25

X

X

X

X

25

GBS M 97-104/25 SK

97-104

3 13/16-4 1/8

25

X

X

X

X

25

GBS M 104-112/25 SK

104-112

4 1/8-4 7/16

25

X

X

X

X

25

GBS M 112-121/25 SK

112-121

4 7/16-4 3/4

25

X

X

X

X

25

GBS M 121-130/25 SK

121-130

4 3/4-5 1/8

25

X

X

X

X

30

GBS M 130-140/30 SK

130-140

5 1/8-5 1/2

10

X

X

X

X

30

GBS M 140-150/30 SK

140-150

5 1/2-5 7/8

10

X

X

X

X

30

GBS M 150-162/30 SK

150-162

5 7/8-6 3/8

10

X

X

X

X

30

GBS M 162-174/30 SK

162-174

6 3/8-6 7/8

10

X

X

X

X

30

GBS M 174-187/30 SK

174-187

6 7/8-7 3/8

10

X

X

X

X

30

GBS M 187-200/30 SK

187-200

7 3/8-7 7/8

10

X

X

X

X

30

GBS M 200-213/30 SK

200-213

7 7/8-8 3/8

10

X

X

X

X

30

GBS M 213-226/30 SK

213-226

8 3/8-8 7/8

10

X

X

X

X

30

GBS M 226-239/30 SK

226-239

8 7/8-9 3/8

10

X

X

X

X

30

GBS M 239-252/30 SK

239-252

9 3/8-9 15/16

10

X

X

X

X

* These sizes are not mechanically locked but spot welded

PU = packaging unit

37

NORMACLAMP® - Hose Clamps

Survey of sizes, band widths & materials

NORMACLAMP® GBS 2-parts

Band width

Clamping Range

Packaging

(mm)

Description

in mm

in Inches

PU

W1

W2

W4

W5

18

GBS M 59-67/18 SK 2T

59-67

2 3/16-2 5/8

50

X

X

X

X

18

GBS M 67-75/18 SK 2T

67-75

2 5/8-2 15/16

50

X

X

X

X

20

GBS M 67-75/20 SK 2T

67-75

2 5/8-2 15/16

50

X

X

X

X

20

GBS M 75-83/20 SK 2T

75-83

2 15/16-3 1/4

50

X

X

X

X

20

GBS M 83-91/20 SK 2T

83-91

3 1/4-3 9/16

50

X

X

X

X

25

GBS M 88-100/25 SK 2T

88-100

3 3/8-4

25

X

X

X

X

25

GBS M 100-116/25 SK 2T

100-116

4-4 9/16

25

X

X

X

X

25

GBS M 116-136/25 SK 2T

116-136

4 9/16-5 3/8

25

X

X

X

X

25

GBS M 136-156/25 SK 2T

136-156

5 3/8-6 5/32

25

X

X

X

X

25

GBS M 156-180/25 SK 2T

156-180

6 5/32-7 3/32

25

X

X

X

X

30

GBS M 125-145/30 SK 2T

125-145

4 15/16-5 11/16

10

X

X

X

X

30

GBS M 145-168/30 SK 2T

145-168

5 11/16-6 5/8

10

X

X

X

X

30

GBS M 168-193/30 SK 2T

168-193

6 5/8-7 19/32

10

X

X

X

X

30

GBS M 193-220/30 SK 2T

193-220

7 19/32-8 21/32

10

X

X

X

X

30

GBS M 220-245/30 SK 2T

220-245

8 21/32-9 21/32

10

X

X

X

X

30

GBS M 245-270/30 SK 2T

245-270

9 21/32-10 3/5

10

X

X

X

X

30

GBS M 270-295/30 SK 2T

270-295

103/5-11 10/16

10

X

X

X

X

30

GBS M 295-320/30 SK 2T

295-320

1110/16-12 3/5

10

X

X

X

X

30

GBS M 320-345/30 SK 2T

320-345

123/5-13 7/12

10

X

X

X

X

PU = packaging unit

Enquiries/ordering:

When making enquiries or placing an order please indicate as follows:

1. Type

2. Clamping Range

3. Band width

4. Material

5. Parts

Example

GBS QR

43-47

20

W1

1-piece

38