NORMACLAMP® - Hose Clamps

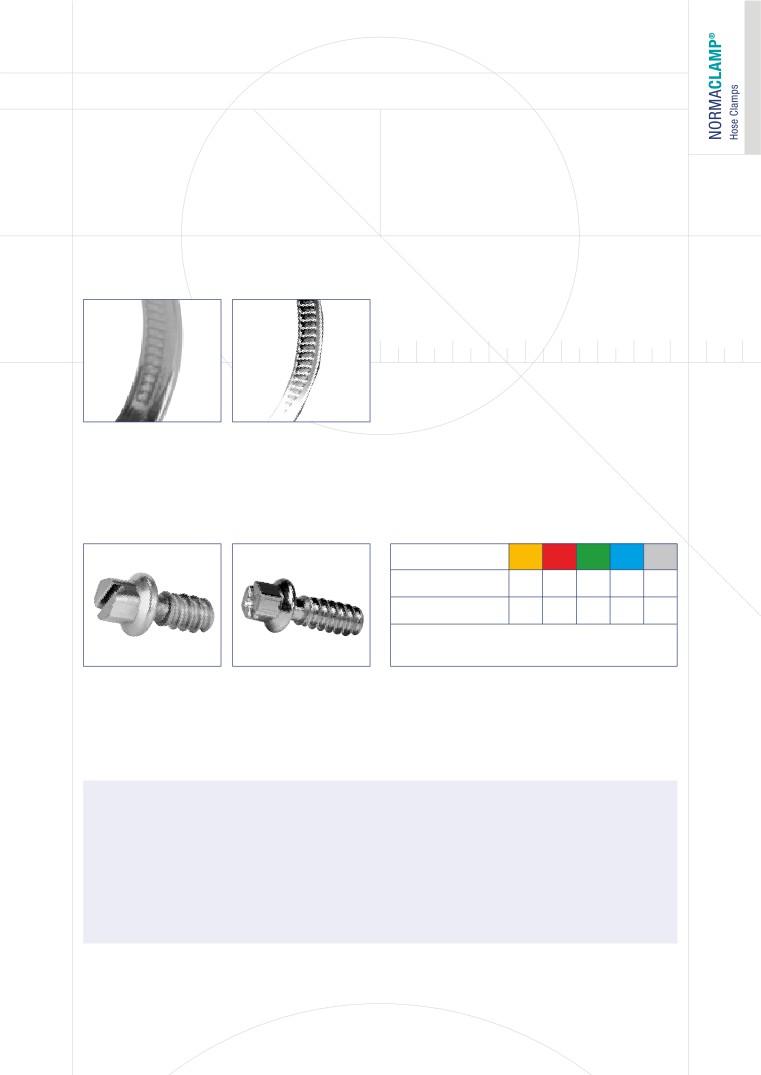

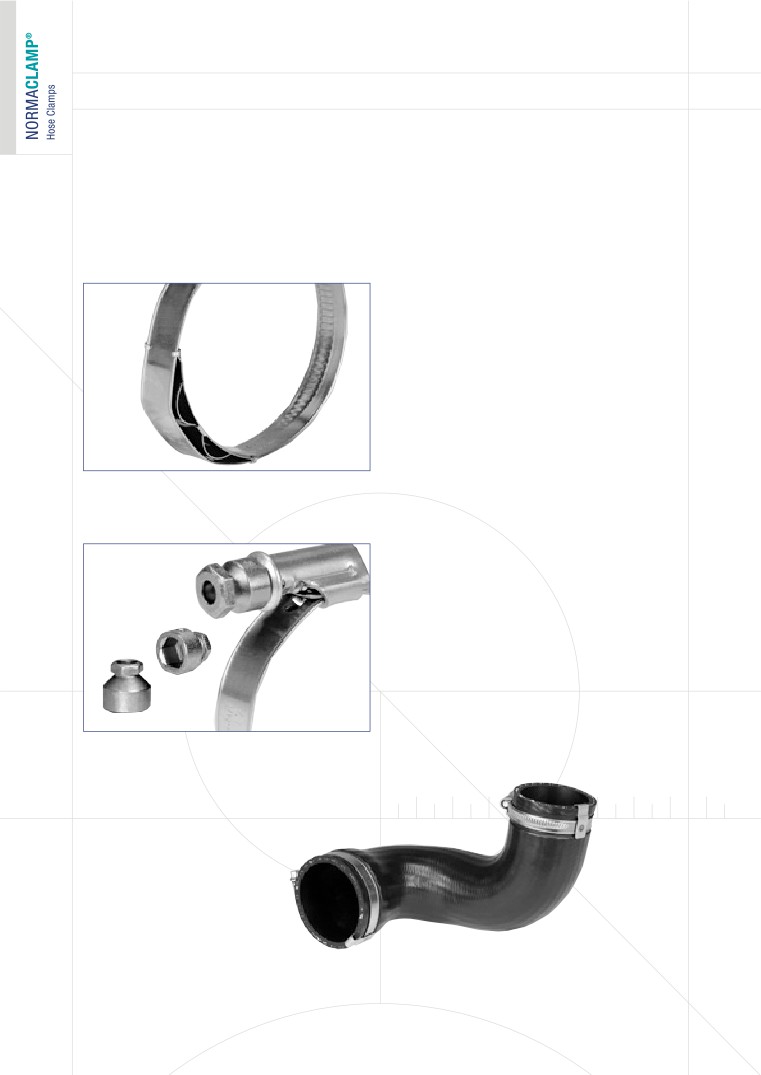

NORMACLAMP® TORRO® -

Since we are continuously working to improve its features

Worm Drive Hose Clips

this clip is still setting standards for modern hose clip design.

to DIN 3017

The distinguishing feature of the NORMACLAMP® TORRO® is

NORMACLAMP® TORRO® hose clips are specially

the asymmetrical construction which tells you at first sight

suitable for applications under high mechanical loads.

whether it is a genuine TORRO® or not.

Short description of technical features

1

4

5

2

3

6

1

Improved asymmetric housing = even distribution of forces

4

Asymmetric extension = prevents the housing from tilting

and safe assembly

over when the clamp is tightened

2

Screw support = Ease of assembly due to the safe

5

Short housing saddle = even contact pressure = improved

guidance of the emerging band end

efficiency

3

Material and clamping range stamped on the band

6

Smooth or stamped inside of band = optimal hose

= prevention of errors

protection

Materials

W1*

W2*

W3

W4

W5

x

x

x

x

x

* No chromium VI used for the coating of the closure components

12

NORMACLAMP® - Hose Clamps

Types of clamp band

Band width 9 mm

• W1 with smooth inside

• W2, W3, W4, W5 with stamped inside

Band width 12 mm

• W1, W2, W3 with smooth inside

• W4, W5 with stamped inside

Screw

W1

W2

W3

W4

W5

Phillips head

SW 7*

•

•

Slotted head

SW 7**

•

•

•

* Band width 7.5 mm = SW 6

** Band width 16 mm = SW 8

The advantages at a glance

• Multi-range hose clamp

• Material: W1, W2, W3, W4, W5

• Chromium VI free: compliant with ROHS, WEEE and ELV Environmental Directives

• Clamping ranges to DIN 3017: 8 - 16 mm up to 140 - 160 mm

• Larger diameters on demand

13

NORMACLAMP® - Hose Clamps

Technical features

High band tensile force and

high fracture torque

As always, the new NORMACLAMP® TORRO® features high tensile

forces. However, when compared with competitor’s products

and the previous model, we now achieve significantly higher

fracture torques. This provides for an increased assembly reliability.

Even clamping force distribution

Thanks to its enhanced technical design, the new

NORMACLAMP® TORRO® range delivers an even distribution

of clamping force. The clamp sits perfectly on the hose and

ensures the optimal sealing of the connection.

Corrosion resistance

Material

Corrosion resistance in salt spray testing

W1

Min. 144 h

W2

Min.

72 h

W3

Min. 200 h*

W4

Min. 240 h

W5

Min. 400 h

* Max 10% corrosion of the base material allowed

Applications

• Cooling water lines

• Depressurized as well as pressurized fuel lines and vent lines

• Oil lines

• Connections in sanitary installations

• Connections in engine construction

• Connections in the white goods industry

• Hose connections in commercial vehicles industries

15

NORMACLAMP® - Hose Clamps

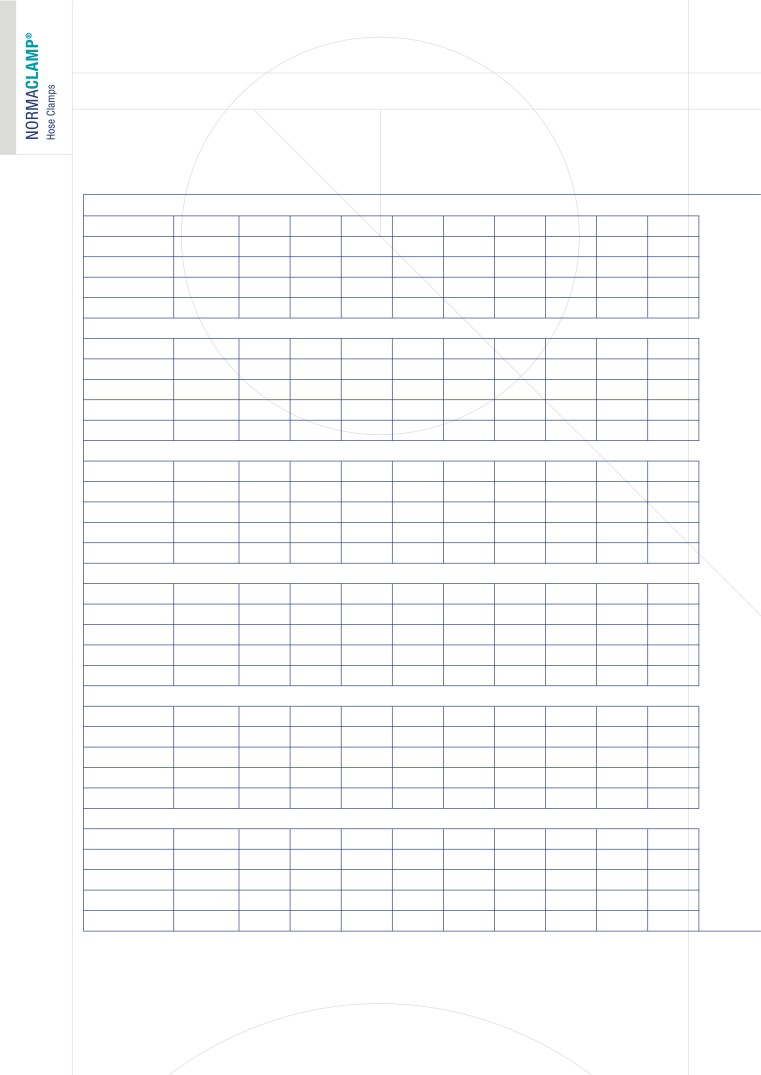

Table with torques

TORRO 9 W1

Diameter (mm)

8-12

10-16

12-18

12-22

16-27

20-32

25-40

30-45

35-50

40-60

AD

2.5 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

LD max

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

PD

3.3

4

4

4

4

4

4

4

4

4

BD min

4

4.5

4.5

4.5

4.5

4.5

6

6

6

6

TORRO 9 W2

Diameter (mm)

8-16

12-22

16-27

20-32

25-40

30-45

35-50

40-60

AD

2 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

LD max

0.7

0.7

0.7

0.7

0.7

0.7

0.7

0.7

PD

2.6

4

4

4

4

4

4

4

BD min

4

4.5

4.5

4.5

4.5

4.5

4.5

4.5

TORRO 9 W3-W5

Diameter (mm)

8-16

12-22

16-27

20-32

25-40

30-45

35-50

40-60

AD

2 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

LD max

0.7

0.7

0.7

0.7

0.7

0.7

0.7

0.7

PD

2.6

4

4

4

4

4

4

4

BD min

4

4.5

4.5

4.5

4.5

4.5

4.5

4.5

TORRO 12 W1

Diameter (mm)

16-27

20-32

25-40

30-45

35-50

40-60

AD

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

LD max

1.2

1.2

1.2

1.2

1.2

1.2

PD

6.5

6.5

6.5

6.5

6.5

6.5

BD min

10

10

10

10

10

10

TORRO 12 W2/W3

Diameter (mm)

16-27

20-32

25-40

30-45

35-50

40-60

AD

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

LD max

1

1

1

1

1

1

PD

6.5

6.5

6.5

6.5

6.5

6.5

BD min

8.0

8.0

8.5

8.5

8.5

8.5

TORRO 12 W4/W5

Diameter (mm)

16-27

20-32

25-40

30-45

35-50

40-60

AD

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

LD max

1

1

1

1

1

1

PD

6.5

6.5

6.5

6.5

6.5

6.5

BD min

8

8

8.5

8.5

8.5

8.5

Legend:

AD = recommended tightening torque in Nm;

LD = no-load torque in Nm;

PD = test torque in Nm;

BD = fracture torque in Nm

16

NORMACLAMP® - Hose Clamps

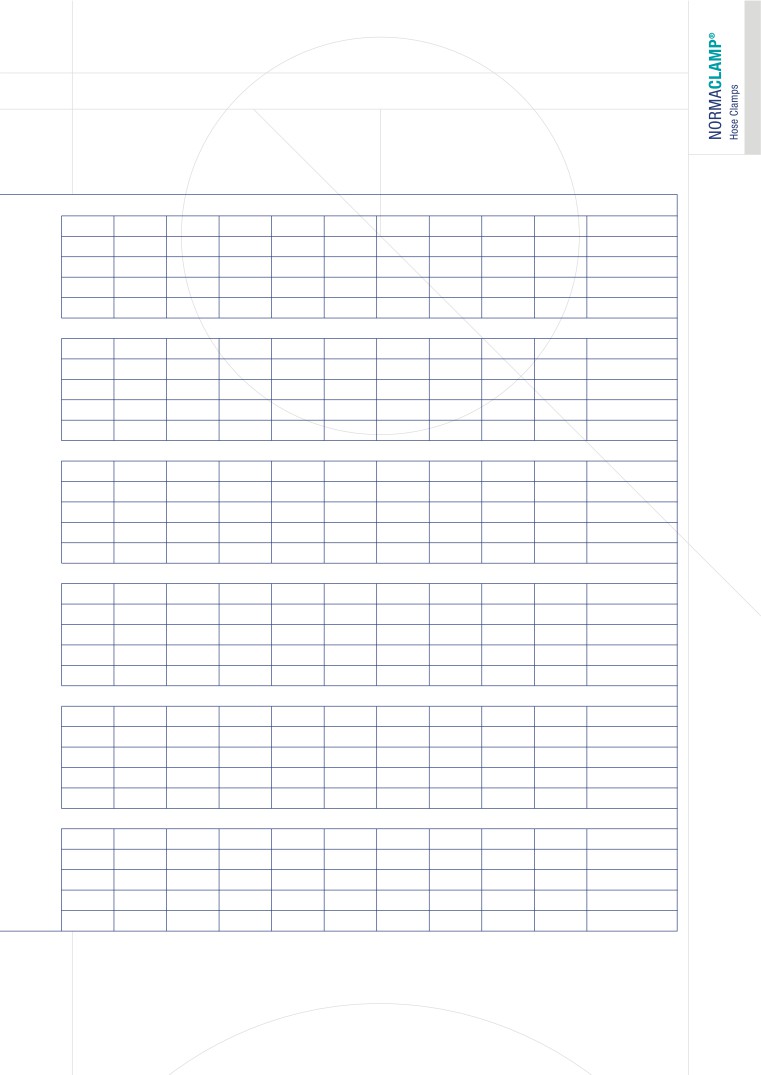

TORRO 9 W1

50-70

60-80

70-90

80-100

90-110

100-120

110-130

120-140

130-150

140-160

Diameter (mm)

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

AD

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

LD max

4

4

4

4

4

4

4

4

4

4

PD

6

6

6

6

6

6

6

6

6

6

BD min

TORRO 9 W2

50-70

60-80

70-90

80-100

90-110

100-120

110-130

120-140

130-150

140-160

Diameter (mm)

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

AD

0.7

0.7

0.7

0.7

0.7

0.7

0.7

0.7

0.7

0.7

LD max

4

4

4

4

4

4

4

4

4

4

PD

4.5

4.5

4.5

4.5

4.5

4.5

4.5

4.5

4.5

4.5

BD min

TORRO 9 W3-W5

50-70

60-80

70-90

80-100

90-110

100-120

110-130

120-140

130-150

140-160

Diameter (mm)

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

3 +0.5

AD

0.7

0.7

0.7

0.7

0.7

0.7

0.7

0.7

0.7

0.7

LD max

4

4

4

4

4

4

4

4

4

4

PD

4.5

4.5

4.5

4.5

4.5

4.5

4.5

4.5

4.5

4.5

BD min

TORRO 12 W1

50-70

60-80

70-90

80-100

90-110

100-120

110-130

120-140

130-150

140-160

Diameter (mm)

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

AD

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.2

LD max

6.5

6.5

6.5

6.5

6.5

6.5

6.5

6.5

6.5

6.5

PD

10

10

10

10

10

10

10

10

10

10

BD min

TORRO 12 W2/W3

50-70

60-80

70-90

80-100

90-110

100-120

110-130

120-140

130-150

140-160

Diameter (mm)

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

AD

1

1

1

1

1

1

1

1

1

1

LD max

6.5

6.5

6.5

6.5

6.5

6.5

6.5

6.5

6.5

6.5

PD

8.5

8.5

8.5

8.5

8.5

8.5

8.5

8.5

8.5

8.5

BD min

TORRO 12 W4/W5

50-70

60-80

70-90

80-100

90-110

100-120

110-130

120-140

130-150

140-160

Diameter (mm)

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

5 +0.5

AD

1

1

1

1

1

1

1

1

1

1

LD max

6.5

6.5

6.5

6.5

6.5

6.5

6.5

6.5

6.5

6.5

PD

8.5

8.5

8.5

8.5

8.5

8.5

8.5

8.5

8.5

8.5

BD min

17

NORMACLAMP® - Hose Clamps

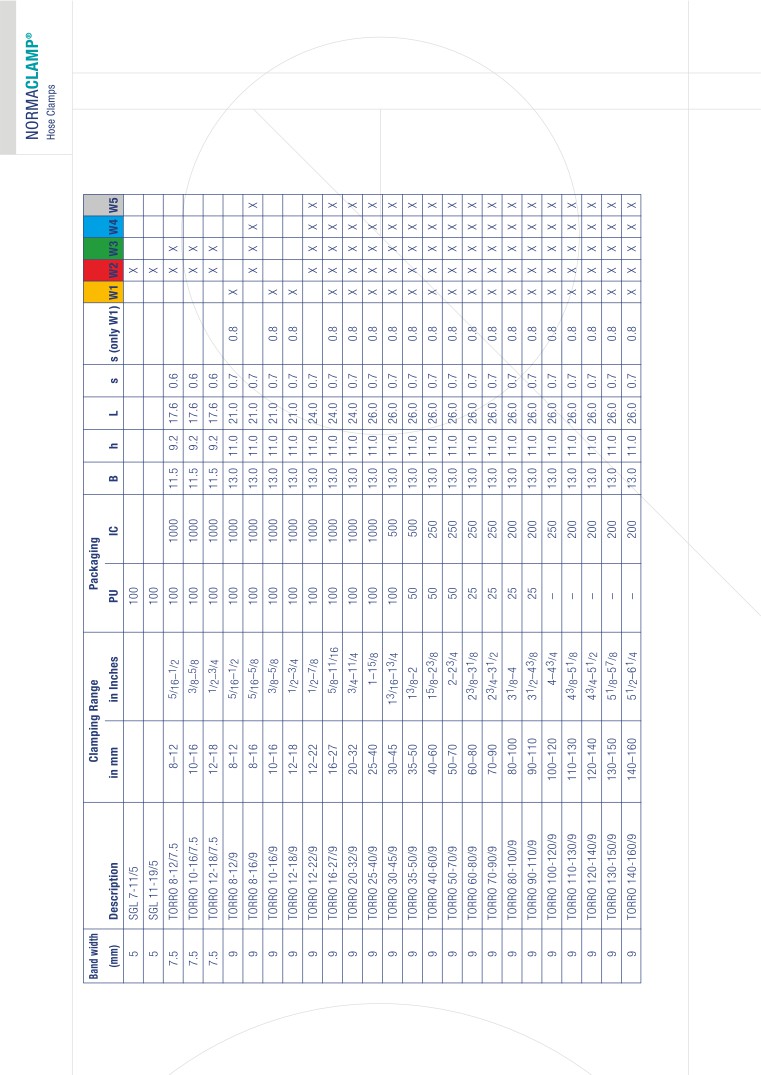

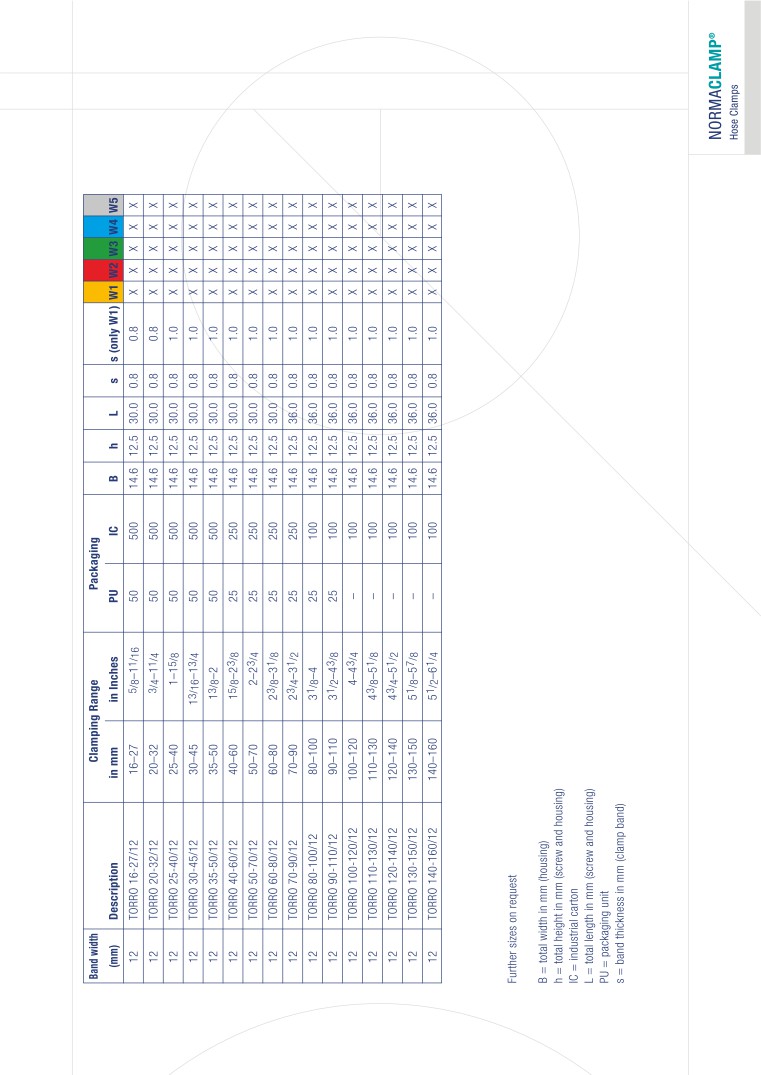

Survey of sizes, band widths & materials

NORMACLAMP® TORRO®

18

NORMACLAMP® - Hose Clamps

19

NORMACLAMP® - Hose Clamps

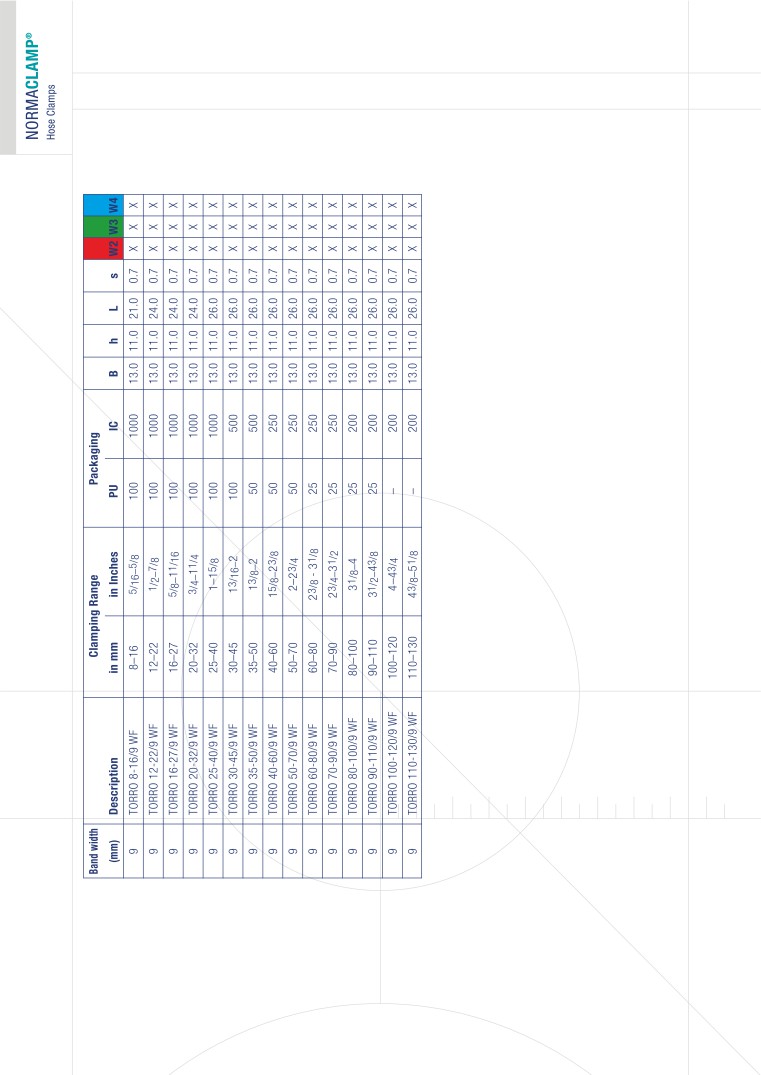

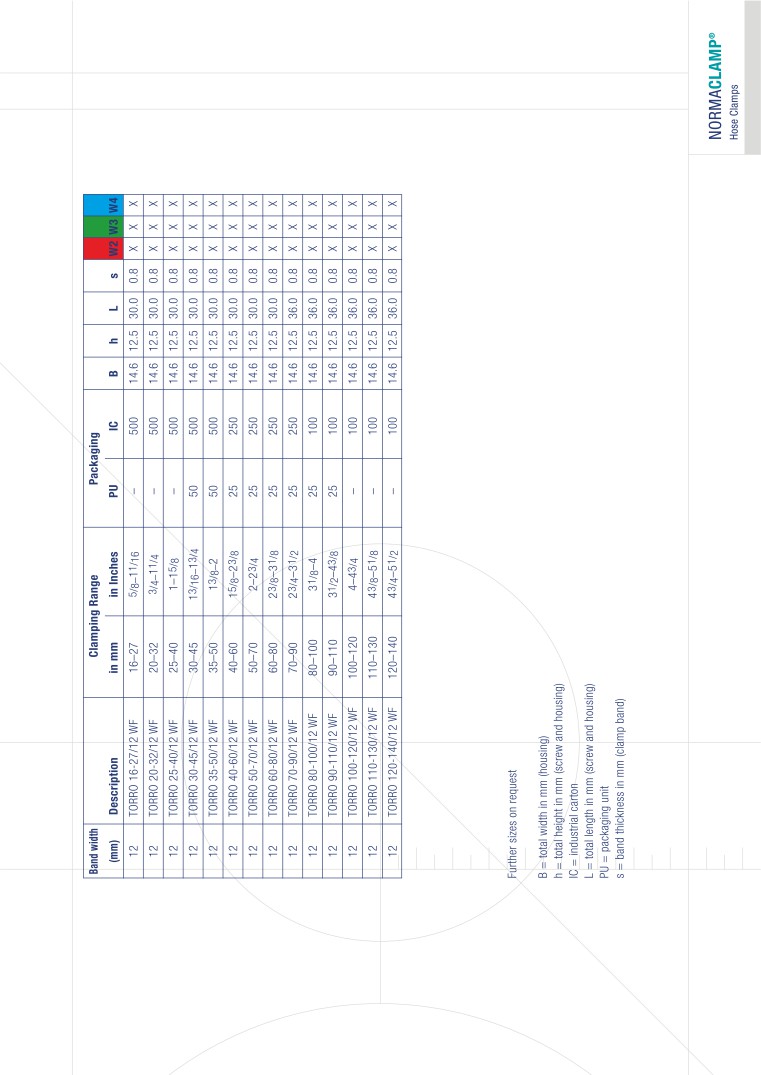

Survey of sizes, band widths & materials

NORMACLAMP® TORRO® WF

20

NORMACLAMP® - Hose Clamps

21

NORMACLAMP® - Hose Clamps

NORMACLAMP® TORRO®

The TORRO® modular system offers several accessories that

Modular System

can be added to the clip, in order to modify its technical charac-

teristics. You are free to combine two or more of these accesso-

ries according to your requirements.

The Notch

The notch is a clever means for pre-positioning the TORRO® hose

clip on the hose. In this case the oval hole in the clamp band

finds its exact counter part on the hose surface. Thus the

TORRO® is safely and accurately kept in place prior to the final

assembly.

Advantage:

• Safe pre-assembly on the hose.

The Clip

With this accessory the TORRO® can also be pre-positioned on

the hose. The two ‘teeth’ of this device keep the TORRO® hose

clip safely in place if it needs to be stocked or transported prior

to its final assembly.

Advantage:

• Safe pre-assembly on the hose

23

NORMACLAMP® - Hose Clamps

The Spring insert

For this version of the NORMACLAMP® TORRO® the standard

hose clip is equipped with a spring insert on the inside of the clip

band. When tightening the screw the spring is loaded and stores

sufficient clamping force to ensure a long-lasting automatic

re-tensioning effect. Thus the radial clamping force achieved

will be sufficient even under extremely low temperatures. There-

fore, the TORRO® is an optimal solution for applications under

extreme temperature changes.

Advantages:

• Automatic re-tensioning effect in the event of hose relaxation

• Increased sealing reliability across a wide temperature range

The Torque Cap

The torque cap cuts off when the permissible torque is reached

and thus saves the need for a torque wrench. Even without the

cap the hose clip still remains adjustable and can be disassem-

bled and/or retightened if necessary.

Advantages:

• Defined tightening torque without special tool

• Visual assembly control

TORRO® pre-positioned using the clip

24

NORMACLAMP® - Hose Clamps

The Safety Collar

The safety collar is an assembly aid consisting of a plastic collar

that is easily fixed on the screw head. It prevents the screwdriver

from slipping off the screw head thus making the assembly

much easier. The safety collar matches our standard screw head

size 7.

Advantage:

• The screwdriver is kept from slipping off the screw head

during assembly

The Thumbsrew

The NORMACLAMP® TORRO® thumbscrew

is easily tightened by hand.

Advantage:

• The TORRO® hose clip can be manually tightened and opened

The Safety-Cap

The NORMACLAMP® TORRO® safety cap is used to prevent in-

juries during assembly work. The small plastic cap covering the

end of the clamp band is one of our contributions to prevent

accidents.

Advantage:

• The NORMACLAMP® TORRO® safety cap is available to fit the

band width 9 mm and 12 mm

Please make sure that the NORMACLAMP® TORRO® accessory you wish to order is suitable for your application.

25